Undergraduate

General Information

Process automation is currently one of the main areas of production in the world. Physical activity and intellectual functions previously performed by humans have gradually shifted to technologies that automate and control processes. In many areas, the role of man is reduced to only operating automatic control devices.

Process automation allows increasing labor productivity and safety many times, solving environmental problems, improving product quality and using human potential more efficiently. Automation and control facilities include industry, agriculture, energy, transport, trade, medicine, etc. technological processes. The Second Karabakh Patriotic War once again demonstrated the invaluable role of automation in the control of drones and other weapons.

The Process Automation Engineering Department at was established at BHOS in 2012 under the name of the Computer and Information and Communication Technologies Department. The department conducts training in two specialties. BHOS started training in the specialty “Process Automation Engineering” in 2013, based on the Bachelor's degree curriculum of Angel Kanchev University of Ruse in Bulgaria.

In 2017, BHOS started enrolling students in the master's degree program in process automation engineering, and in 2020, the university began enrolling students in the doctoral degree program in this specialty.

Learning outcomes

Graduates of the Process Automation Engineering Department are employed by both local and foreign companies. Many of these companies, including SOCAR, BP, ABB, Emerson Process Management, Avandsis Group, Schneider Electric, SOCAR KBR, BP Exploration, Wood Group, NÖC&A and etc., manufacture and implement industrial products and automation systems. Graduates of this department can work as specialists in designing , creation and operation of methods and tools used for automating production processes, designers of CAD systems, production process mechanization and optimization engineers, programmers, etc. They can also work in the non-industrial sectors, for example, in the sphere of automation of multi-dwelling buildings and individual houses.

Laboratories

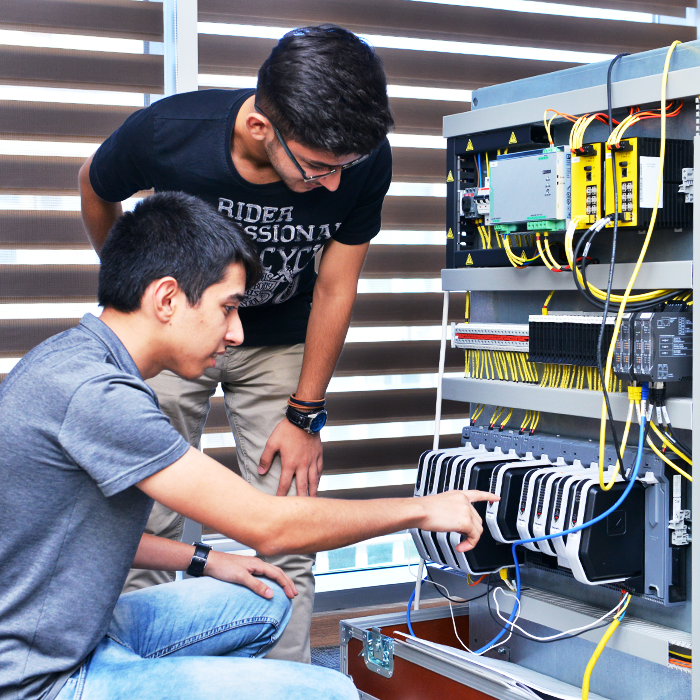

The modern laboratories created at the department are divided according to their purpose. During their studies, students convert their theoretical knowledge into practical skills by experimenting in the laboratories of the department. Working in the laboratories, students master the basic principles of automation and information security. Students model and simulate real processes in computerized classrooms of the department using special programs.

The Process Automation Engineering Department has ten learning laboratories and one Research Center. In the process control laboratory, which was donated to BHOS by the company EMERSON, students majoring in process automation engineering get acquainted with control and measuring devices, pumps, control systems, design and manage small processes and monitor processes with wireless control systems.

In the Electric Power and Machines Laboratory, equipped with the equipment made by the German company LUCAS-NUELLE, students carry out experiments realted to the subjects such as Electrical Machines, Electromechanical Devices, Smart Houses.

The Microcontroller Lab includes EasyPIC v7 hardware, PIC Microcontroller technology, Basic, Pascal or C programming languages, and microsystems. In this laboratory, students carry out experiments related to the subject of microprocessors.

The laboratory also has SIMATIC S7-300 universal programmable controllers made by the company SIEMENS, which are used for controlling machines and devices.

In the Programmable Logic Controllers Lab, students learn the principles of operation of controllers, programming languages and perform relevant tasks using the SIMATIC S7-300 controllers. This laboratory is also used in the teaching of the subject “Industrial Computer Networks”. With the help of COM3LAB equipment, students learn the operation of industrial computer networks and get acquainted with network models and protocols.

In the Process Control and Automation Laboratory, students carry out experiments related to the subject “Technological Process Automation”. Students carry out measurements with field devices and monitor certain processes using TRICATION software.

In this laboratory, equipped by the company ABB, learn the basic principles of operation of SCADA systems, SCADA hardware, SCADA systems software and protocols, modern approaches and methods for process control and data acquisition, etc.

Students learn the operation of Supervisor Management and Data Collection Systems get information about SCADA systems, using 800xA Distributed Control System, and get acquainted with control and measuring devices.

In the Electrical Engineering and Measurement Laboratory, students learn subjects such as Electrical Engineering, Electrical Measurements, Electrical Materials and Devices, Digital Electronics, Analog Electronics.

The laboratory, developed as part of ELOTRAIN courses, is equipped by the multifunctional three-phase power supply, plug-in system, oscilloscopes, multimeters and other equipment made by LUCAS-NUELLE. Students perform laboratory tasks under the guidance of a teacher, build electrical circuits with plug-in components, provide them with a multifunctional power supply, take measurements and observe the result through an oscilloscope.

The Robotics Center is used by all course students. At this center, students independently prepare for startup projects, robot and drone Olympiads, and other competitions. Senior students and masters conduct research using the equipment available at the center.

Experience and career opportunities

In order to get students acquainted with the operation of equipment in the real working conditions, on-the-job internships are organised for 3rd and 4th year students.

After four years of internships, 5th year students and 2nd year master students undergo a 10-week research internship to prepare dissertations and collect materials for dissertations. This experience increases their research potential and, therefore, plays an important role in building their future careers.

Students undergo summer internships at various enterprises operating in fields of the automation and oil and gas industry, where they get acquainted with the operation of various equipment, work processes, technological parameters, control systems, as well as learn health, safety and environmental protection regulations.